United Kingdom

R&D recap: the Journal of Ammonia Energy

Ahead of the 3rd Symposium on Ammonia Energy in Shanghai next month, we take the opportunity to highlight select papers and key results from the first two editions, starting with the 2022 Cardiff event:

- In an ammonia-diesel blending study, Orleans University and WinGD found that minimising the diesel fraction actually led to increased N2O emissions.

- In a bid to produce an optimal ammonia-hydrogen fuel blend, a University of Birmingham team characterised the ammonia cracking mechanism of a new, transition metal-promoted lithium amide catalyst.

- A KAUST study of swirl intensity of an ammonia-methane blended fuel finds that increasing the swirl number leads to a more compact flame, reducing NOX emissions.

- A team from the University of Minnesota found that combustion durations comparable to gasoline were obtained for ammonia-hydrogen fuel blends.

- And, as part of a joint academic-industry session on safety, it was recommended that a careful, proactive approach is taken towards new ammonia users, likely exposure risk points and deploying maritime ammonia fuel.

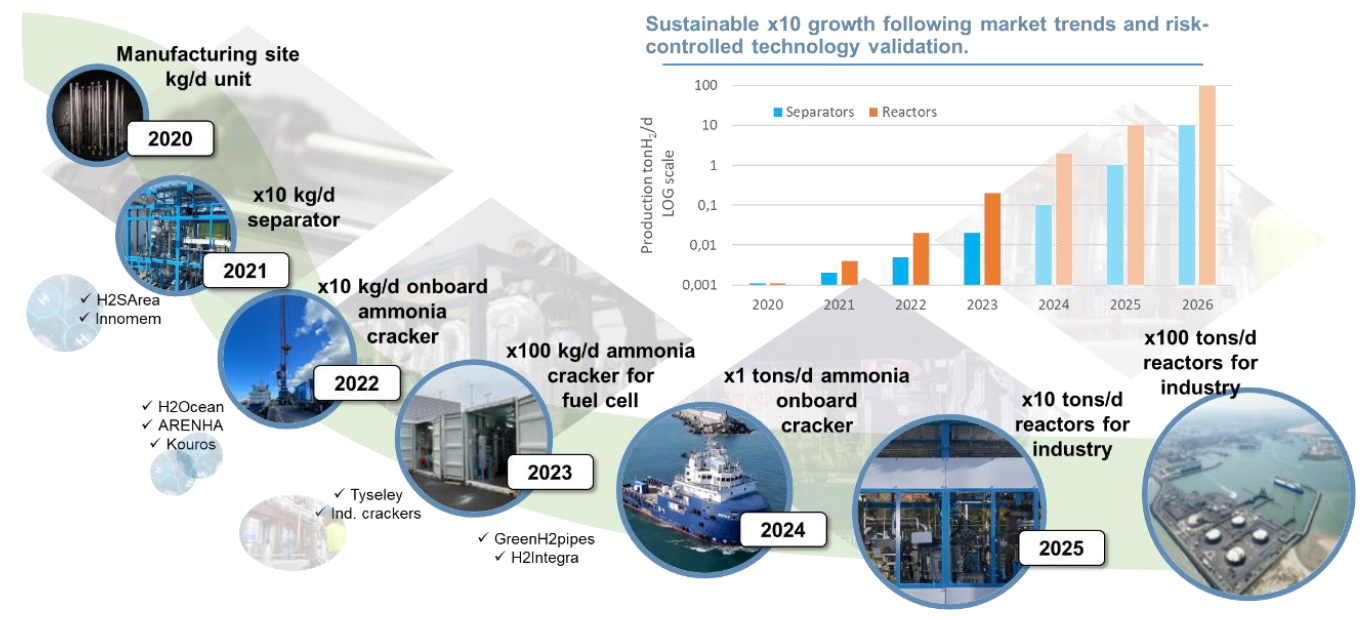

Ammonia cracking in H2SITE membrane reactors

In our May episode of Project Features, H2SITE joined us to explore the development history of their Palladium membrane-based, ammonia cracking technology. Learn more about the deployment of this technology at a hydrogen vehicle refueling site in the UK, plus plans for scaling-up the technology to produce tons per day of fuel-cell grade hydrogen from ammonia.

Onboard cracking, fuel storage and adhering to emissions standards: highlights from the MariNH3 conference

At last month’s MariNH3 conference in Nottingham, a series of keynotes laid out the opportunities and challenges ahead for marine ammonia fuel. Onboard ammonia cracking technologies are moving through testing phases and closer to commercialisation, vessel designers are working through the unique challenges of carrying ammonia fuel onboard, and emissions mitigation technology (in combination with adherence to existing Tier 3 standards) will be necessary to ensure that ammonia-powered vessels are more environmentally-friendly than conventional counterparts.

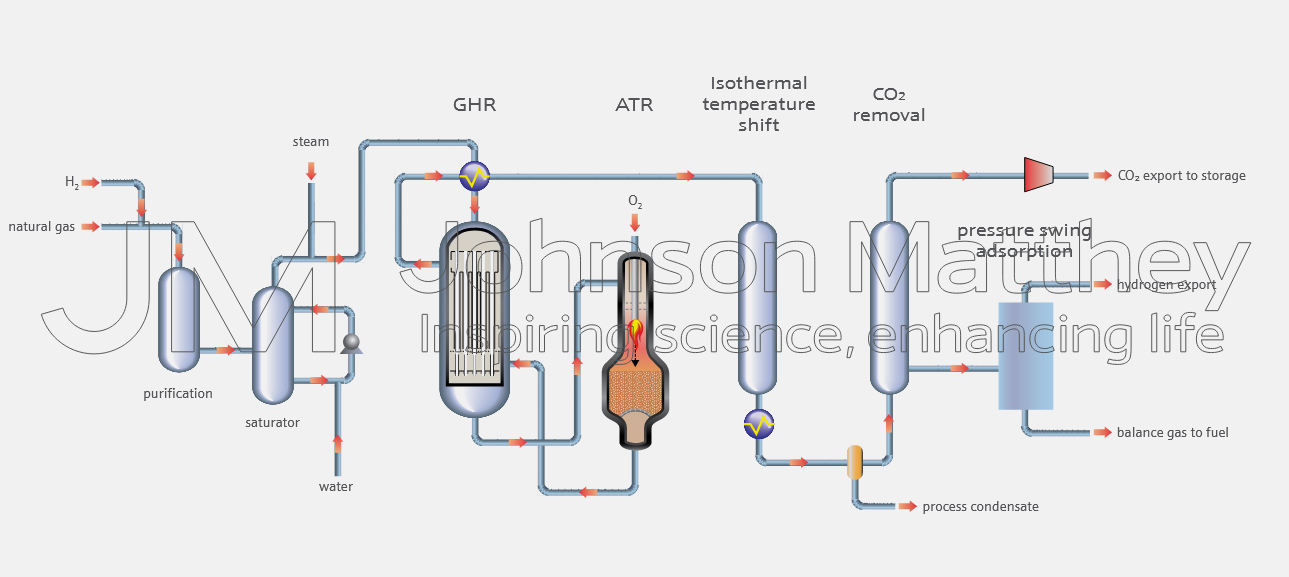

Johnson Matthey and thyssenkrupp: CCS-based ammonia technology to market

Two big players, Johnson Matthey and thyssenkrupp Uhde, will combine their CCS-based hydrogen and ammonia synthesis technologies to offer a new “blue” ammonia solution, enabling production with up to 99% CO2 capture.

Ammonia cracking in H2SITE membrane reactors: producing fuel cell-purity hydrogen in Birmingham, UK

Meet H2SITE to explore its catalytic membrane technology for ammonia cracking, the Ammogen project in the UK, maritime applications and other opportunities.

Heidelberg Materials: ammonia cracking for cement production

Heidelberg Materials and partners will conduct a feasibility study on the use of ammonia as a hydrogen carrier for cement production. In the trials, a cracked ammonia fuel mix will power cement clinker production at Heidelberg’s Ribblesdale site in the UK.

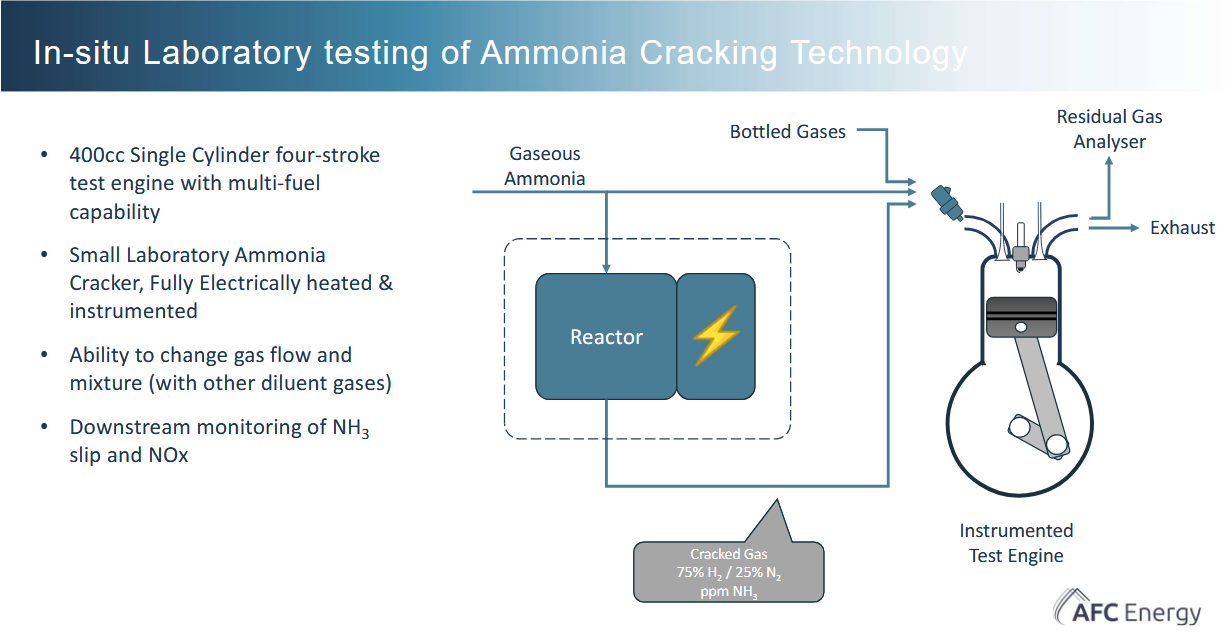

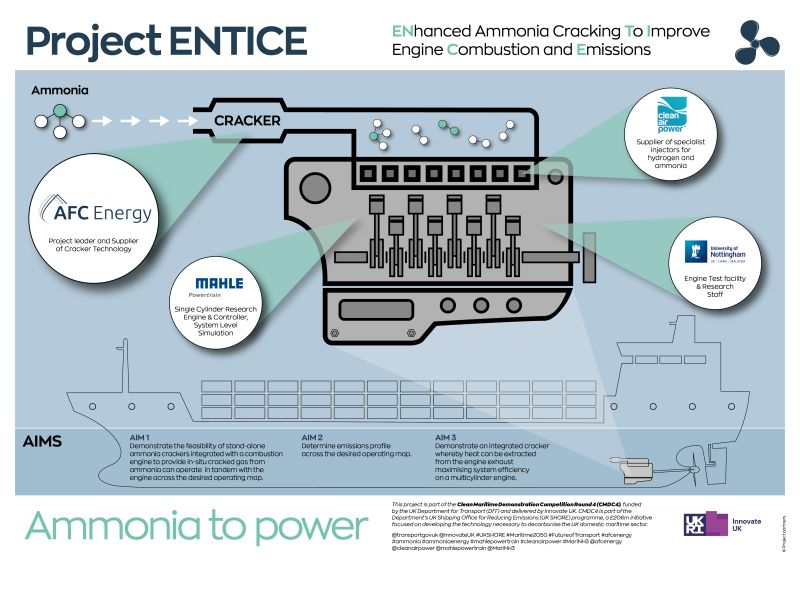

Marine ammonia combustion engines under development in the UK

AFC Energy, MAHLE, the University of Nottingham and Clean Air Power have been awarded funding from Innovate UK to demonstrate the feasibility of ammonia combustion engines in the marine sector, based on the integration of AFC Energy’s ammonia cracking technology. The new program builds on a prior R&D program exploring ammonia combustion engines for the off-road construction industry.