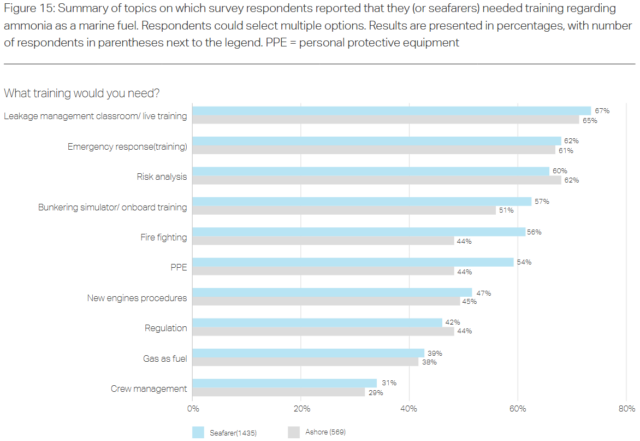

The Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping has released results from a new survey of over 2,000 workers across the maritime community. While a majority of workers indicate their willingness to sail on ammonia-fueled vessels, this support is contingent upon comprehensive training that addresses all concerns and operational aspects of working with ammonia. Live training, operational experience and proactive communication will all be required to increase confidence in the new fuel.

Global

Liebherr: ammonia fuel for the mining sector

Liebherr and Italy-based Bruno Generators will embark on a joint development project exploring ammonia fuel for off-grid power generation in the mining sector. Building off “promising” results in Liebherr’s own internal trials with ammonia fuel, future applications could include power for heavy vehicles like electric excavators.

IMO moves forward with interim guidelines for ammonia fuel use

Approval of interim guidelines for the use of maritime ammonia fuel is anticipated at an upcoming IMO committee meeting in December, giving the shipping industry its first international standard for the safe operation of vessels using marine ammonia fuel.

Licensor selection picking up for renewable ammonia synthesis loops

One of the key steps in project development is the selection of the licensor for the renewable ammonia synthesis loop. For renewable ammonia projects, licensors including KBR, Topsoe, Thyssenkrupp Uhde, Casale, and Stamicarbon offer a range of technologies and services covering small to large-scale ammonia production. We explore these different technology offerings, as well as the growing list of projects where they are being deployed.

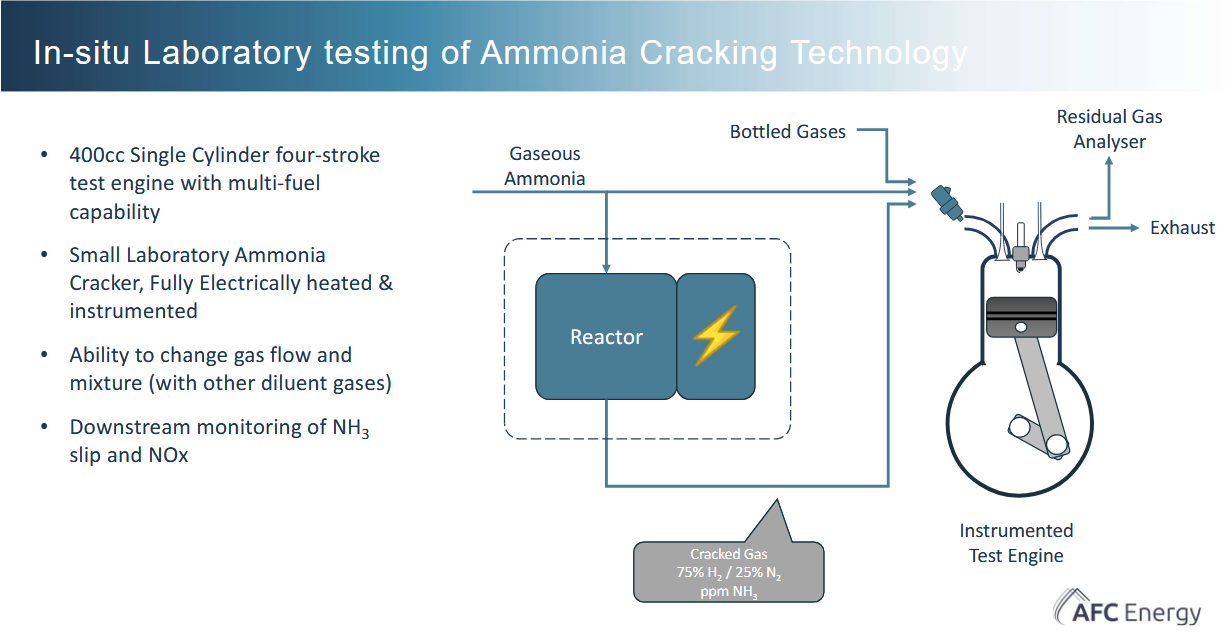

Onboard cracking, fuel storage and adhering to emissions standards: highlights from the MariNH3 conference

At last month’s MariNH3 conference in Nottingham, a series of keynotes laid out the opportunities and challenges ahead for marine ammonia fuel. Onboard ammonia cracking technologies are moving through testing phases and closer to commercialisation, vessel designers are working through the unique challenges of carrying ammonia fuel onboard, and emissions mitigation technology (in combination with adherence to existing Tier 3 standards) will be necessary to ensure that ammonia-powered vessels are more environmentally-friendly than conventional counterparts.

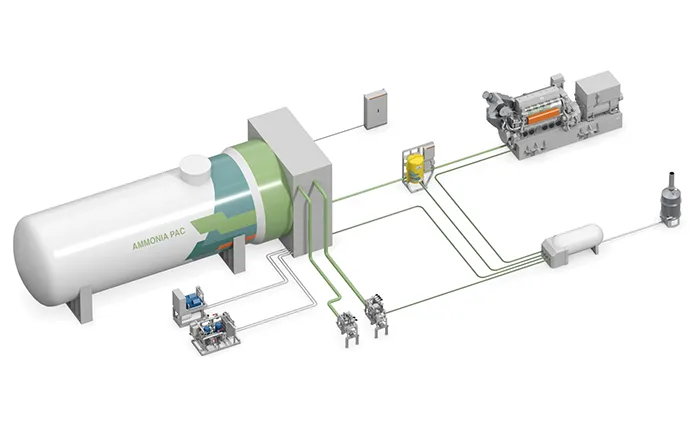

Ammonia marine fuel supply systems: Wärtsilä and Amogy

Wärtsilä Gas Solutions will now provide the ammonia fuel supply and cargo handling systems for all six of EXMAR’s dual-fuel vessels being built in South Korea. Meanwhile, Amogy and Mitsubishi have completed concept designs for two onboard systems: a powertrain combining ammonia cracking and hydrogen fuel cell for ships, and a hydrogen supply facility to provide hydrogen as pilot fuel to an ammonia-fueled engine.

Chicken or Egg? GH2 proposes solutions to the off-take trilemma

The Green Hydrogen Organisation (GH2) has released a report sketching out considerations for hydrogen off-take agreements. It emphasises the importance of balancing risks between prospective buyers and sellers, given the challenges facing a nascent market. It also analyses the respective merits of fixed & variable pricing models, supply regulation and other key off-take provisions.